Plasma - SwiftCut 3000 Pro

Plasma cutters were probably one of the most interesting and impressive tools developed in the 20th Century. Since then, they have improved dramatically, and are one of the most widely used metal plate cutting processes for a large variety of industries.

Plasma cutters use the basic principles of physics, along with some gas and electricity, to cut shapes and holes out of metal. Once an industrial machine, Plasmas are now used by artists and hobbyist's alike. It is as common to find a plasma cutter in a sculptors studio as it is to find one in an engineering workshop.

How does it work?

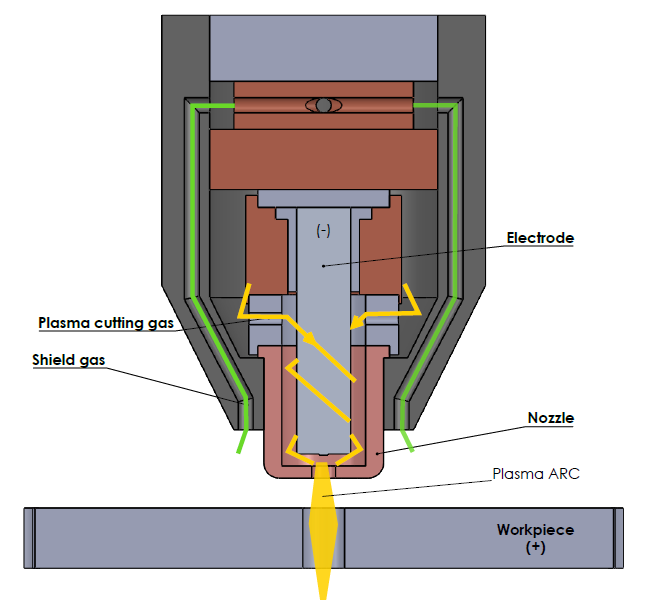

A plasma cutter uses gas and electricity. The gas is forced through a constricted opening at high pressure, at which point it contacts an electric arc that is sent through a nozzle. This process causes a reaction, and the gas (typically nitrogen, argon, oxygen, etc.) is heated to such a degree that it enters the fourth state of matter, plasma. The plasma is so hot that it can melt through metal at a high enough speed that the excess material is blown away resulting in a relatively clean cut. Different gases can be used depending on material type and thickness.

A Plasma is limited in what materials it can cut. For best results, it should be used primarily for steel, and conductive materials do not tend to cut well on the plasma. Thickness is also a factor in plasma’s cutting capabilities. The quality will begin to decline on anything above 1/2” in thickness.

If you have any queries regarding the plasma or profiles you would like cut, give us a call.