Waterjet - Omax Maxium 1530

Waterjets have been around since the 1950's and are widely recognised as one of the most efficient cutting methods on the market. They can cut through almost any material, and have no limitation on thickness they can cut.

They use a high pressure jet of water to cut through materials. To put the amount of pressure used into perspective, water from the tap in the kitchen comes out at around 60psi, whereas a waterjet puts out a pressure of nearly 90,000psi.

How does it work?

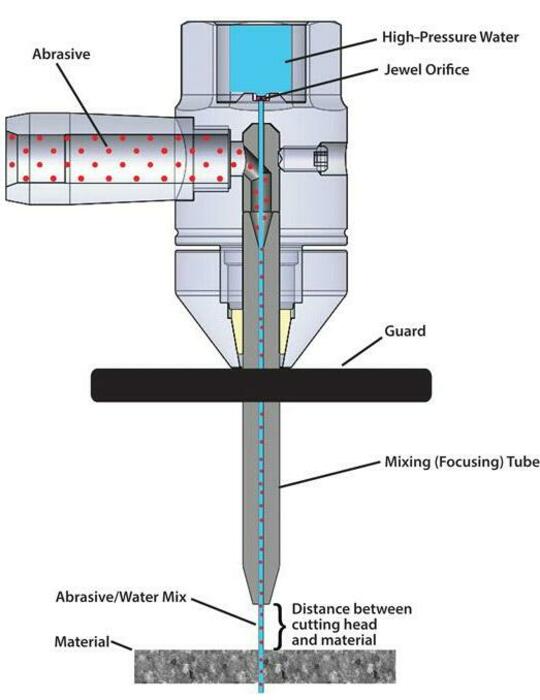

A high pressure pump generates a flow of pressurised water which travels through a water line and through the cutting head. The flow continues on to the abrasive waterjet nozzle. Inside the nozzle, the pressurised water flow passes through a very small diameter orifice to form a jet of water. The jet then passes through a venturi section where a metered amount of garnet (abrasive granule) is pulled into the stream of water. This mixture of water and garnet passes through a ceramic mixing tube, creating a slurry that exits the nozzle at a very high speed. This stream of water and garnet travels with enough speed and pressure to cut through materials up to 300mm thick.

Our waterjet has a cutting area of 1500mm x 3000mm and can cut through most materials.

Below is a list of materials the waterjet can cut:

- Aluminium

- Stainless Steel

- Brass

- Copper

- Carbon Steel

- Titanium

- Tool Steel

- Mild Steel

- Ceramic Tile

- Glass

- Granite

- Leather

- Marble

- Wood

- Carbon Fiber

- Fiberglass

- Foam

- Rubber

- Acrylic

The waterjet allows us to cut an extensive amount of profiles. From parts as simple as squares or circles, to large detailed cut outs of a world map, the waterjet can pretty much do it all.

We welcome the opportunity to cut new material and designs. If you have any questions regarding the waterjet system/specs or parts you want cut, give us a call.

Be sure to check out our gallery for some insight into a few of the things our machine can cut.